Pioneering Excellence in Southeast Asia: A Malaysian Bird’s Nest Producer’s Journey with ZLPH Retort Sterilization Technology

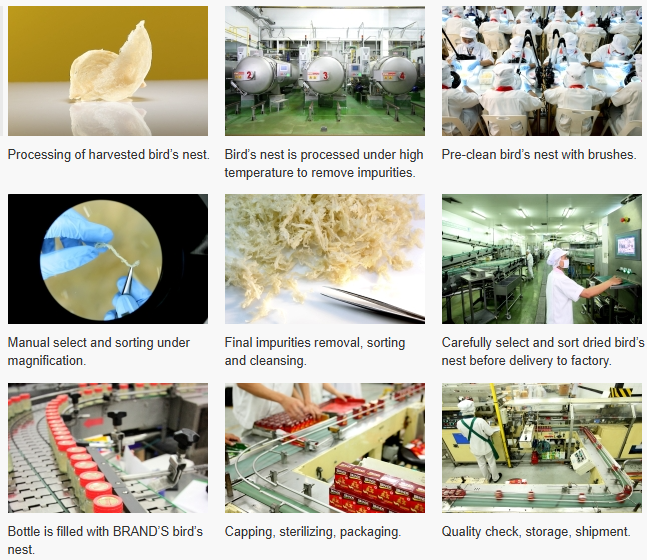

In the high-value, precision-driven world of edible bird's nest processing, few challenges are as critical—and as delicate—as achieving flawless Bird's Nest Sterilization. For a leading Malaysian processor renowned for supplying premium-grade bird's nest to discerning markets across Asia, maintaining product safety without compromising the delicate texture, natural color, and bioactive integrity of the nest was the paramount operational hurdle. After an extensive global search for a technological partner, they selected ZLPH MACHINERY to engineer a bespoke sterilization solution. This collaboration centers on the implementation of an advanced retort autoclave system, specifically customized for the unique demands of Bird's Nest Sterilization. This case study details how ZLPH’s food retort machine technology has become the cornerstone of this Malaysian leader’s quality assurance and market expansion.

The Challenge: Balancing Sterilization with Uncompromised Quality

Edible bird's nest, a revered delicacy, is extraordinarily sensitive to thermal processing. Traditional or improperly calibrated heat treatment can easily cause over-processing, leading to undesirable texture loss (dissolution), nutrient degradation, and color darkening—factors that drastically diminish market value. The Malaysian processor needed a retort machine that could deliver guaranteed Commercial Sterilization to meet stringent international food safety standards (addressing pathogens like Salmonella), while operating with a level of gentleness and precision unheard of in standard canning lines. Their existing methods could not reliably achieve this balance, creating a bottleneck for scaling production while upholding their premium brand promise.

The ZLPH Solution: A Custom-Engineered Retort Autoclave for Bird’s Nest

ZLPH MACHINERY responded not with a generic retort canning machine, but with a fully customized food retort machine solution, engineered from the ground up for Bird's Nest Sterilization. The core of the solution was a state-of-the-art retort autoclave featuring revolutionary soft-retort technology.

1、Precision Gentle-Heat Technology: Unlike conventional retort machines designed for robust vegetables or meats, ZLPH’s system utilizes a proprietary low-agitation, saturated steam-air mix process. This creates a uniform thermal environment with minimal mechanical stress, ensuring the fragile, thread-like structure of the bird's nest remains intact throughout the Bird's Nest Sterilization cycle.

2、Micro-Precision Process Control: The heart of the system is an advanced PLC with multi-stage programmable logic. It allows for exquisitely precise control over the temperature ramp-up, sterilization hold, and controlled cooling phases. This prevents thermal shock, ensuring the Bird's Nest 3Sterilization process eliminates microbiological risks while meticulously preserving the product’s cherished sensory and nutritional properties.

3、Guaranteed Sterility and Traceability: The retort autoclave is validated to achieve a consistent F0 value, delivering documented Commercial Sterilization. Every batch processed in the food retort machine is accompanied by complete digital traceability reports—logging time, temperature, and pressure data—which are indispensable for audits and for building trust with regulators and end-consumers in markets like China and Singapore.

4、Versatile and Hygienic Design: While specialized for bird's nest, the retort machine is designed to handle the glass jars and premium pouches used for final packaging. Its full 316 stainless-steel construction and CIP (Clean-in-Place) capability meet the highest hygiene standards required for premium food production.

Implementation and Transformational Outcomes

The project featured close collaboration. ZLPH’s engineers conducted a thorough site analysis in Malaysia before installation, ensuring seamless integration into the existing clean-room processing environment. Comprehensive training empowered the local team to master the new retort autoclave operations.

The results have fundamentally elevated the processor’s capabilities:

Unprecedented Quality Consistency: The ZLPH food retort machine has eliminated batch-to-batch variability. The sterilized bird's nest consistently retains its ideal shape, crystalline color, and desired soluble solid content, directly translating to higher product grading and value.

Validated Safety for Market Access: The company now possesses irrefutable process validation data, enabling smoother export certification and compliance with the stringent import regulations of key markets, effectively using the retort machine as a passport for global trade.

Enhanced Brand Reputation and Trust: By implementing this cutting-edge Bird's Nest Sterilization technology, the processor has solidified its reputation as a technologically advanced and trustworthy supplier. This investment is a powerful marketing asset, demonstrating a tangible commitment to purity and safety.

Operational Scalability: The automated, reliable cycles of the retort autoclave have increased throughput predictability and capacity, allowing the business to confidently accept larger orders and plan for growth.

A Strategic Partnership Defining Industry Standards

For this visionary Malaysian processor, the partnership with ZLPH MACHINERY transcended a typical equipment purchase. It represented a strategic investment in proprietary Bird's Nest Sterilization capability. The ZLPH retort autoclave is more than a retort canning machine; it is a dedicated food retort machine system that protects the very essence of their premium product. This case exemplifies how ZLPH collaborates with industry leaders to solve unique challenges, providing not just a retort machine, but a complete technological foundation for quality leadership, safety assurance, and sustainable growth in the sophisticated global arena of premium food processing.